Quality control system

The quality management system is the factory's life system. The company has established and strictly implemented a sound food safety and quality management system. From the source control of raw materials of food control, product design, product development to product production, it always adheres to the quality policy of "strict control and assurance of quality and safety", and fully guarantees that the consumer can enjoy safe and delicious ready-to-eat aquatic products.

1. Infrastructure

Make the design and layout in strict accordance with the GB14881. The process equipment, flow and logistics layout processing area should be reasonable, without causing cross-contamination.

Equipment and tools should adopt corrosion-resistant and rust-resistant stainless steel that is easy to clean and disinfect.

Equipment and tools should be designed to be smooth, durable and easy to disassemble and clean, and their installation should be in line with the process of health requirements;

Implement regular maintenance and calibration of the equipment, and conduct the measurement test on metrical instruments.

Regularly perform air filtration, purification, and sterilization in the production workshop to ensure production cleaning.

2. Source control

Conduct the audit and approval of the quality system of all raw materials suppliers, to ensure from the source that the quality of raw materials is reliable for production.

The procurement department and quality control departments should conduct on-site audit on the scale of production, plant facilities, equipment, file systems, quality standards and inspection conditions in the location of supplier units.

Conduct review on the supplier's business license, production license, product implementation standards, quality inspection reports and related information.

The supplier passing the review is a qualified supply unit that will be subject to regularly return visit.

3. Personnel control

Food processing personnel should have health examination every year, to obtain a health certificate; conduct pre-job training on key operator, who will be qualified to work only after assessment;

All practitioners should receive regular training of national laws and regulations, such as food safety law training, food safety national standard training;

4. Process control

Prepare HACCP plans for each product, identify key control points, and conduct regular monitoring, verification, and recording;

Food processing plant temperature should always be controlled below 15 ℃, the product temperature should be controlled below 10 ℃. The processing time should be short to ensure food safety;

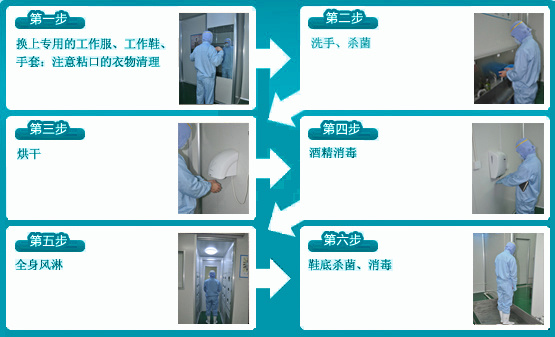

Conduct regular cleaning and disinfection control on personnel and equipment in product production, and conduct regular monitoring;

Product storage and transport should be kept in cold chain state, and product temperature should be controlled at -18 ℃ or below -18 ℃.

5. Inspection control

Sign a quality assurance undertaking with the supplier. The raw materials for acceptance should be higher than the national standard or industry standard, and reject those materials that don’t meet it.

Strengthen process inspection. Conduct inspection and supervision on intermediate products based on product technical standards, and the next process can be validated only after the products meet the standards;

As for each product, develop internal control standards, and its technical standards should be stricter than the national food safety standards;

6. File control

Complete file management system is the support for the running of quality assurance system.

Technical standards documents include product process specifications, production methods, inspection procedures, etc., which are essential basis for production operation and inspection operations.